Kimberley Cherrington of Microban International explores how incorporating built-in antimicrobial technologies into surfaces within healthcare settings can reduce the spread of infection and the amount of waste sent to landfill

Healthcare settings produce considerable quantities of waste, with estimates as high as 538,600 tonnes of waste produced by the NHS annually.

The NHS therefore recognises that it has not only a social responsibility to reduce its environmental impacts, but also a legal and financial one, given the implementation of strict legislation and the continual rise in landfill tax.

Various NHS divisions, including NHS Supply Chain and NHS Property Services, have already committed to schemes for waste reduction and they aim to achieve this by implementing efficient recycling programmes and providing sustainable alternatives to single-use products, ultimately reducing the amount of waste that lines our landfills.

A turning point

Materials contaminated with micro-organisms are often the first to be discarded to prevent microbes from spreading to other surfaces.

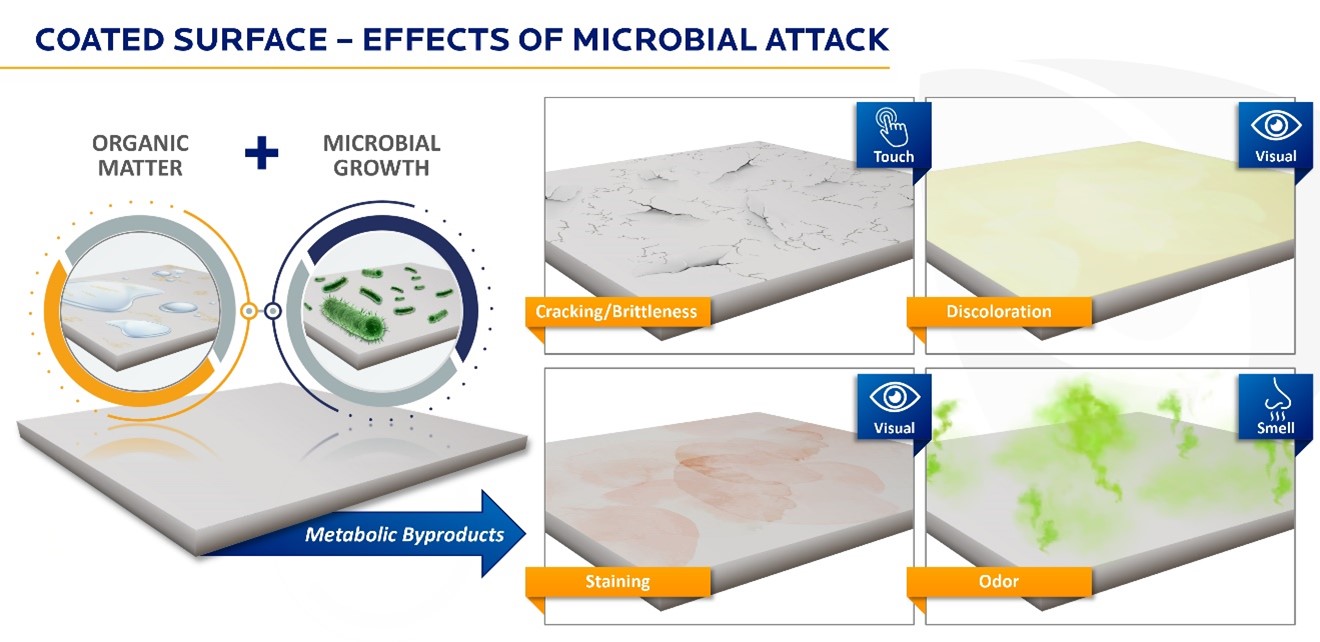

If left to grow, microbes can cause unpleasant odours, staining, and biodegradation (figure 1), significantly reducing patient comfort and creating concerns about a lack of cleanliness.

Healthcare providers are obliged to ensure this does not happen and that rigorous cleaning routines are in place to keep surface contamination to acceptable levels.

However, the combination of record-breaking visitor numbers, staff shortages, and funding cuts makes it almost impossible to keep every high-touch surface sanitised, as most disinfectants offer limited residual activity once the surface has dried.

And this is where single-use products were previously heralded for their ability to be quickly disposed of, rather than cleaned.

However, environmental pressures mean that the healthcare industry is at a turning point, moving away from wasteful disposables to more-durable, easy-to-clean, and reusable materials.

Reducing waste

Numerous healthcare product manufacturers are responding to this demand for products that aim to reduce waste by incorporating built-in antimicrobial technologies into various surfaces – from privacy curtains and bed sheets to foam mattresses and medical carts – to help prevent the growth of microbes (figure 2).

Working behind the scenes 24/7, built-in antimicrobial technologies complement regular cleaning schedules to keep surfaces cleaner, and thwart the onset of odours and material degradation.

Numerous healthcare product manufacturers are responding to this demand for products that aim to reduce waste by incorporating built-in antimicrobial technologies into various surfaces

This extends the durability and usable lifetime of treated products, avoiding their early disposal and preventing them from ending up in landfill or recycling plants prematurely.

And this can ultimately help to reduce the waste that healthcare centres produce, and the associated financial burden of product replacement.

Restoring comfort

Hospital mattresses are good examples of how healthcare environments can benefit from antimicrobial product protection.

These items are hotspots for microbial growth, and are often covered to keep them protected.

However, the FDA released a safety alert to healthcare providers after receiving hundreds of reports of mattress covers failing to protect the foam underneath.

Over time, these surfaces wear away, allowing microbes to penetrate the protective layer and forcing hospital operators to dispose of both the cover and mattress.

MicroGuard is an innovative antimicrobial solution from Microban that can be incorporated into foam mattresses to help prevent the growth of microbes and provide around-the-clock product protection.

Crucially, the active ingredients in MicroGuard are metal-free and proven to be non-leaching, offering a more-favourable regulatory profile compared to traditional antimicrobial technologies for foam, such as arsenic-based OBPA.

While this antimicrobial technology is not a substitute for regular cleaning, it does provide additional peace of mind that these surfaces are staying hygienically cleaner while in use or storage.

Textile solutions

Bed linen and various other textiles in hospital wards can also harbour microbes, so should be properly handled, stored, decontaminated, and disposed of when necessary.

While this antimicrobial technology is not a substitute for regular cleaning, it does provide additional peace of mind that these surfaces are staying hygienically cleaner while in use or storage

However, institutions have varied laundering requirements, often only changing linens between patients and replacing fabric curtains if they are visibly soiled or there is a high perceived risk of contamination.

DuraTech by Microban is an antimicrobial technology with superior wash durability designed explicitly for cotton textile applications.

This ground-breaking, non-heavy-metal technology helps to prevent the growth of odour-causing microbes, even after 75 launderings, far exceeding the current industry standards.

And fabrics can be treated with this technology during manufacture to help keep them fresher and cleaner in between launderings, restoring patient comfort.

Working with the experts

There are clear, tangible benefits to incorporating antimicrobial technologies into a range of different products to build cleaner and more durable environments, so healthcare manufacturers are increasingly turning to this tried-and-tested method.

But, as these technologies are being introduced into patient areas, it is important to select an antimicrobial that aligns with a trust’s sustainability goals, is appropriate for the application, and has a favourable regulatory status.

There are clear, tangible benefits to incorporating antimicrobial technologies into a range of different products to build cleaner and more durable environments, so healthcare manufacturers are increasingly turning to this tried-and-tested method

Microban offers a portfolio of BPR-notified technologies, and can provide crucial expertise to gain the most from each chemistry.

In summary

Waste reduction is becoming an increasingly important issue for healthcare providers, as centres strive to be more sustainable.

There is a push to switch from single-use products to longer-lasting and more-durable alternatives that will not add to the mountains of waste in landfill or the need for recycling.

Antimicrobial technologies can be incorporated into goods during manufacture to help protect surfaces from the growth of micro-organisms, keeping odours and biodegradation from causing irreparable damage and increased maintenance costs.

Together with regular cleaning, this can help to meet both cleanliness and sustainability targets, reducing the environmental burden of healthcare waste and delivering added peace of mind for both patients and healthcare professionals.