Paul Allen from CMD, a specialist in underfloor power distribution systems, discusses the use of busbar powertrack in a Nightingale field hospital and what can be learned for future hospital development and emergency response

With two vaccines now being rolled out to the UK population, there is hope that we may finally be on a path to tackling the COVID-19 virus and taking pressure of the NHS.

While there remains a long road ahead, there will be opportunities to consider what has been learned from the pandemic in terms of hospital specification and design and the redeployment of non-hospital assets as field hospitals.

Flexible infrastructure

Among the key elements in influencing the selection of locations for Nightingale field hospitals was the electrical infrastructure in the existing building and the potential to adapt this to accommodate the hospital layout.

This made conference centres and event venues an obvious choice because they already contain flexible services designed to enable frequent reconfiguration.

Opting for this kind of building was not possible in all locations, however, and it is from the buildings where electrical infrastructure had to be installed quickly to create additional capacity that we can learn the most about potential future healthcare building services strategies.

A new approach

One of the smaller, local facilities chosen as a Nightingale Hospital was the Sir Tom Finney Sports Hall at the University of Central Lancashire (UCLan) in Preston.

The sports hall has a solid floor and had insufficient electrical infrastructure for use as a hospital, so two new distribution boards were installed, along with a diesel generator to provide standby power in the event of an outage.

The fitout included installation of a timber floor above the existing floor and modular bays, which were fabricated offsite to enable 120 patients to be treated if required.

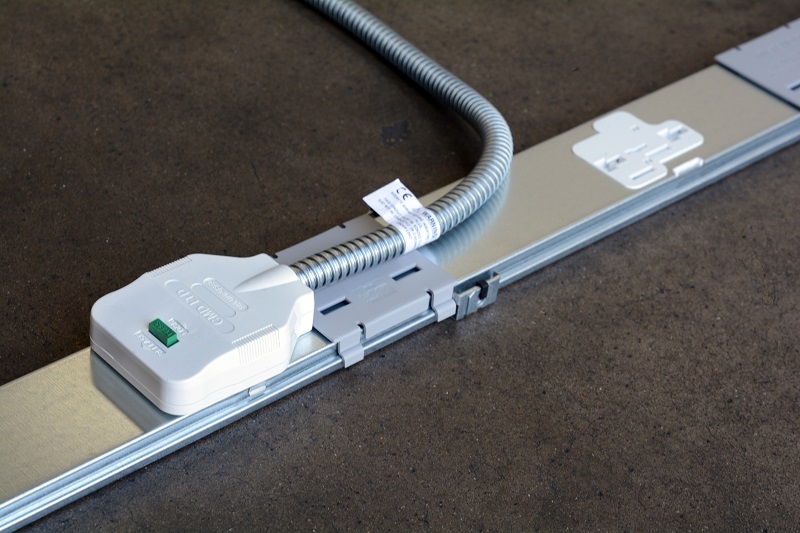

To aid rapid installation of the electrical distribution required for each bed bay, CMD’s Betatrak busbar power track system was used.

This plug-and-play busbar system is not often specified for hospital environments, but it provided the ideal solution for fast and consistent installation with sufficient capacity and flexibility for each bed bay.

Contractor, Interserve Engineering Services, installed the power track by fixing it to the walls of each prefabricated bay.

Plug and play

One run of powertrack provided the electrical distribution to five beds, with a tap-off for each bay to provide four twin sockets for each bed along with a light switch.

RCD protection was included at the end of every tap off lead for each bay.

The plug-and-play nature of the powertrack system meant the team was able to install the entire electrical distribution system for 120 beds within 24 hours in two 12-hour shifts.

While busbar is not always the most-appropriate electrical distribution technology for use in hospitals, what the Nightingale Hospital in Preston teaches us is that it provides the ideal solution for rapid deployment of healthcare infrastructure and for modular patient bed capacity.

The sections of powertrack click together quickly and simply and tap offs to provide local power connectivity can be installed on a plug-and-play basis at 300mm intervals, with RCD protection at the end of each tap off lead.

CMD’s 63A Betatrak busbar system provides additional flexibility and can be specified in standard, clean earth (CE), dual circuit, auxiliary and three-phase, providing the potential for designated and protected electrical networks often required in hospital environments.

Long-term strategies

Once the vaccination programme has taken effect, hopefully the crisis in NHS capacity will be over in the short term, but it’s important that we use it to consider longer-term strategies for emergency response and asset development.

Modular construction is already becoming increasingly common in the development of hospital buildings.

And the plug-and-play nature of busbar powertrack systems makes them extremely compatible with this approach to consistent replication, and suitable for rapid installation in patient modules at scale.

In any future public health emergencies, busbar systems should also be considered the method of choice for creating rapid, safe, and resilient electrical distribution networks in repurposed buildings or modular builds within hospital estates.