Ian Thomas, product manager for LabControls at TROX UK, reveals how effective measures can reduce laboratory energy costs and carbon emissions while maintaining safety and air quality

The recent energy crisis has added new urgency to the ongoing drive towards carbon reduction in hospital and healthcare sites. Laboratories and testing facilities are a particular concern, as their energy consumption is often more than three or four times that of offices on a square metre basis. And this can mean that laboratory buildings are responsible for between 50%-80% of the total energy related carbon emissions of research-intensive teaching hospitals. Improving environmental performance of laboratory spaces is therefore a matter of urgency, but energy efficiency projects in these spaces require careful consideration. It is essential that the health and safety of staff, researchers, and other building occupants is not compromised by inadequate air management. The integrity of testing and research outcomes also relies on the correct environmental conditions being maintained. Effective measures implemented in these high energy consumption spaces, however, can make a major contribution to carbon reduction and cost savings for the site as a whole.

TACKLING ENERGY WASTAGE

An immediate priority is to identify unnecessary energy consumption when laboratories are unoccupied. It may be possible to set the Building Management System (BMS) to reduce air change rates overnight or at the weekend and local overrides can be used to ensure that, if personnel should be working outside of usual work hours, the air changes can be re-established at times when the BMS has put the building into reduced mode. A review of air change rates across the site as a whole will also identify if the settings of different zones are appropriate for the activities carried out in each space.

TAKING CONTROL

Another priority is to investigate the operation of fume cupboards, as these are responsible for a significant proportion of laboratory energy consumption due to their higher-than-average demand for conditioned air. A 900mm-wide fume cupboard with a maximum sash height of 500mm and face velocity of 0.5 m/s would extract approximately 225 l/s of conditioned air from the room. And this demand for conditioned air has a significant knock-on effect across the site, driving up the energy consumption of air conditioning system components such as air handling units, chillers, and fans. Firstly, it is vital to ensure that all fume cupboards are capable of variable air volume (VAV) operation, as this reduces extraction automatically when the sash is closed. For the example above, this figure drops from 225 l/s to just 55 l/s when the sash is down, reducing the conditioned air requirement by 170 l/s. Transitioning fume cupboards from constant to variable air volume has significant energy-saving potential. Next, consider minor changes to the day-to-day operation of fume cupboards that could unlock further energy savings. Sashes are often left open when individuals are away from the fume cupboards, resulting in unnecessary consumption of conditioned air. A retrofittable passive infrared (PIR) sensor can identify that no one is present at the fume cupboard and, after a set time, a visual or audible alarm is triggered to indicate that the sash have been left up. An auto sash closer can then work in conjunction with the sensor to close the sash automatically, preventing unnecessary extraction of conditioned air. It is also quite common for fume cupboards to have additional control features that are already resident, but not currently configured for operation. Contact the manufacturer, or a lab air management specialist, to investigate whether existing hardware has additional energy saving features that could be brought into operation.

ROOM AIR MANAGEMENT

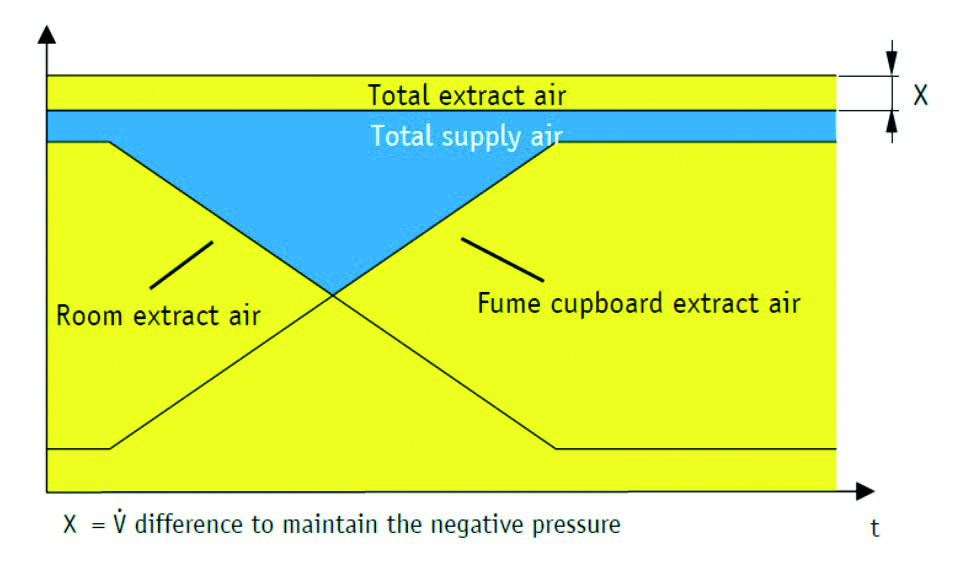

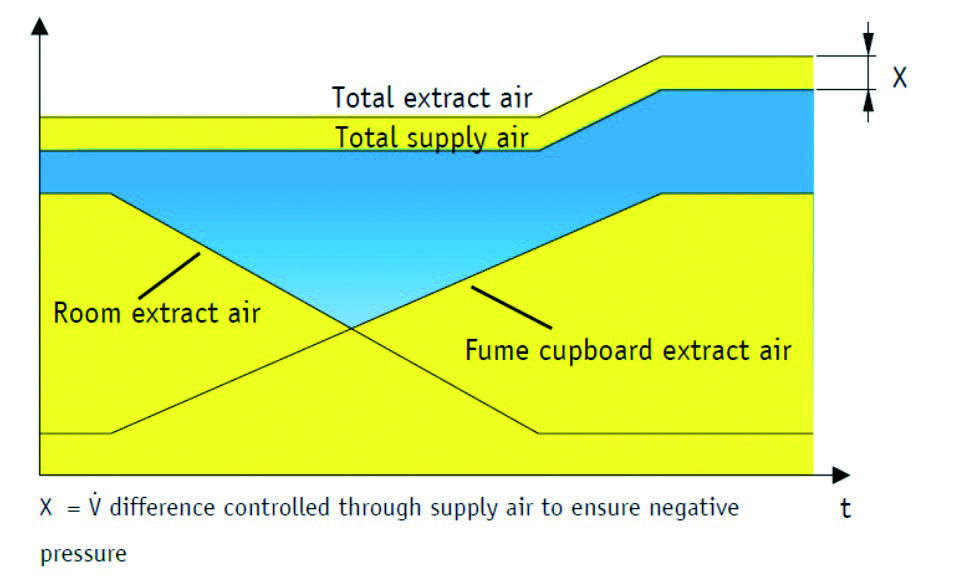

For the most-significant carbon reductions and energy savings, though, install a room air management system. This will provide automatic control of all input and extract air forthe laboratory, ensuring the required ventilation strategy and levels of safety are maintained while optimising energy efficiency. If the fume cupboards are open and extracting air, there is not the same requirement for the room system to carry out this process. The TROX EASYLAB system, for example, scales down room exhaust air extraction automatically in line with fume cupboard extraction. This prevents energy wastage associated with over supply of conditioned air and improves environmental performance significantly (see Figures 1 and 2).